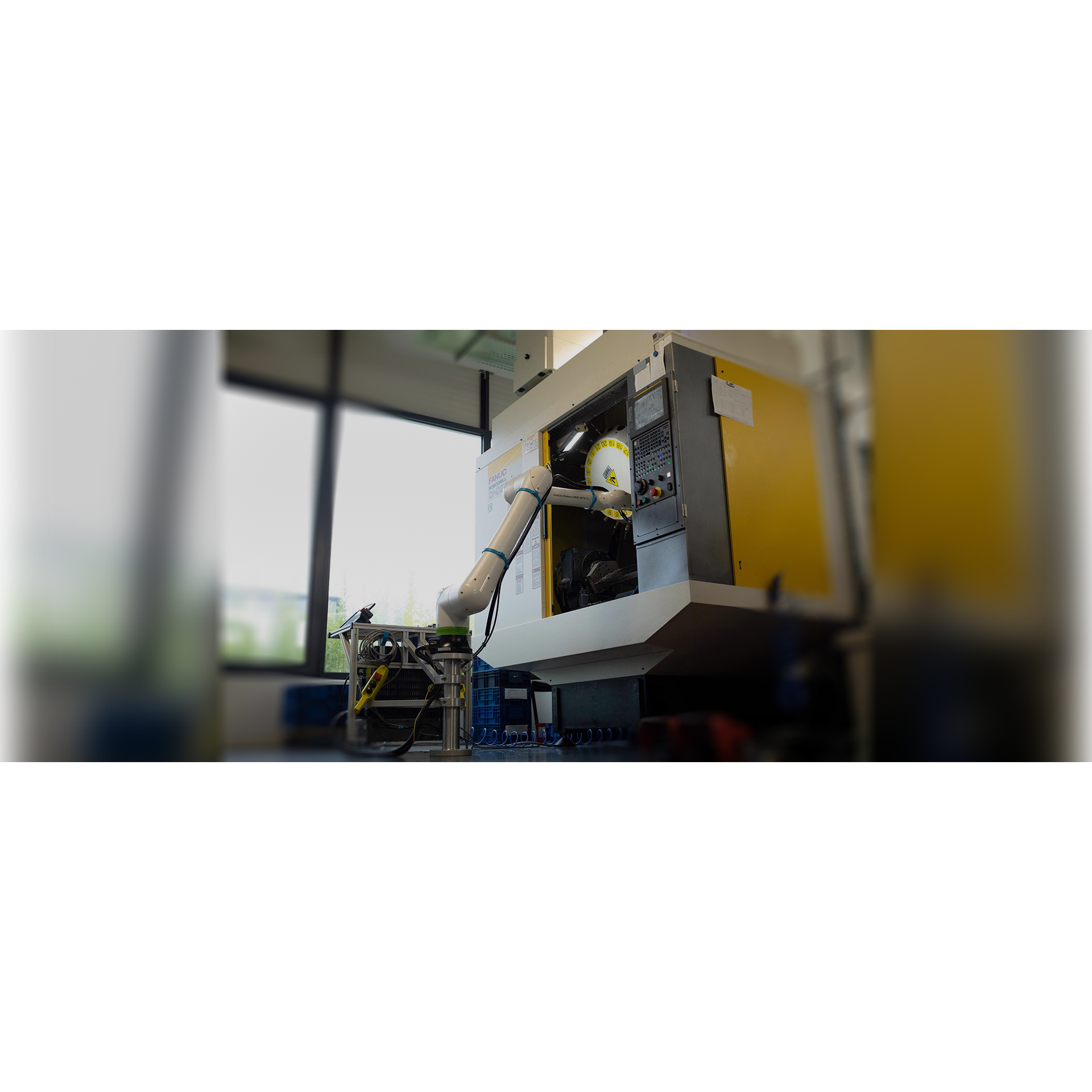

If you have had a bad experience with automation, we recommend using the Pilot Implementation service, which involves installing a COBOX test station at the customer's premises. The station is adapted to work with the machine and to support the product specified by the customer. The implementation is handled by Cobot Planet Application Engineers.