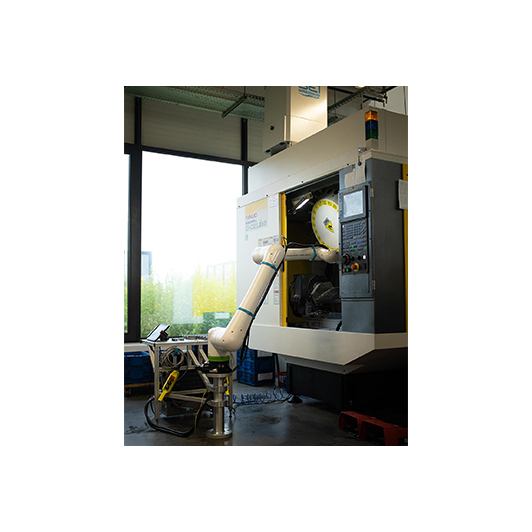

COBOX is a complete mobile station, developed by machining specialists, automation specialists and software developers for operating CNC machine tools. It is ideal for operating milling machines and turret lathes. The COBOX solution consists of hardware designed by the Cobot Planet team (patented C-Interconnector, workpiece storage system, cobot foundation system) and proprietary Machine Tending Expert Software (MTEX Software). Depending on the configuration, COBOX includes best-in-class collaborative robots from the Universal Robots and FANUC brands, as well as proven collaborative grippers from OnRobot and Robotiq. Thanks to the use of these solutions, it is possible to use the workstation without additional fences and safety features.

✓ COBOX offers configurability in three dimensions!

✓ The proprietary C-Interconnector enables communication in every range.

- Configurability - several workstation configurations are possible (depending on individual needs).

- Compactness - the advantage of cobots over traditional industrial robots is their slimness, as well as the fact that they do not need to be enclosed for safety purposes (once all requirements have been met)..

- Mobility - low weight and easy assembly allow the workstation to be moved seamlessly between machines.

- Flexibility - depending on your needs, thanks to racks and plates for positioning and storing workpieces, the COBOX can be configured to work in a limited working space and to store as many workpieces as possible, ensuring extended unattended operation of the machine.

- Ease of use - thanks to dedicated algorithms, the operator uses ready-made recipes and does not have to worry about complicated code.

- Safety - the COBOX workstation is CE marked. This means that it has been designed and built in accordance with the requirements of the Machinery Directive and related standards. This is the highest safety standard, ensuring that the COBOX is a finished and ready to use device.

- Communicability - the exchange of signals between the machine tool and the workstation is seamless, thanks to the proprietary C-Interconnector.

- Innovation - the interchangeable gripper fingers are created by 3D printing, so they can be perfectly adapted to the workpiece being produced, and the entire workstation can be easily adapted to handle the next assortment.

- Repeatability - ensures quality and stability in production.

COBOX is a ready-to-use completed machine (CE certificate). Immediate delivery from stock and an installation time of no more than 8 hours for the COBOX station allows the benefits of automation to be obtained instantly. This is an unsurpassed standard of implementation and customer service in the automation industry offered by the Cobot Planet team. Just as importantly, COBOX gives the user the freedom to implement new assortments.

See what we have prepared for you and choose the best automation path!

ROBOWIZARD Software - professional software for easy self-management of robotic workstations (FANUC and UR-series). We set ourselves the goal of developing an application-specific software package that meets the following requirements:

- the developed recipes are to perfectly reflect the hardware configurations found in the CNC industry (type of machine tool, number of spindles/vices);

- it should enable the user to work independently, easily and comfortably with the robot (including handling assortment changes);

- it should enable entrepreneurs and managers to quickly train employees to work with the cobot;

- it should ensure high safety standards for the use of the cobot in accordance with current standards.