Thanks to the configurability of COBOX, the customer can select the most cost-effective and optimal solution for their own production needs. Flexible automation significantly reduces machine downtime, increasing maintenance-free machine tool uptime, which leads directly to company profits.

COBOX offers configurability in three dimensions:

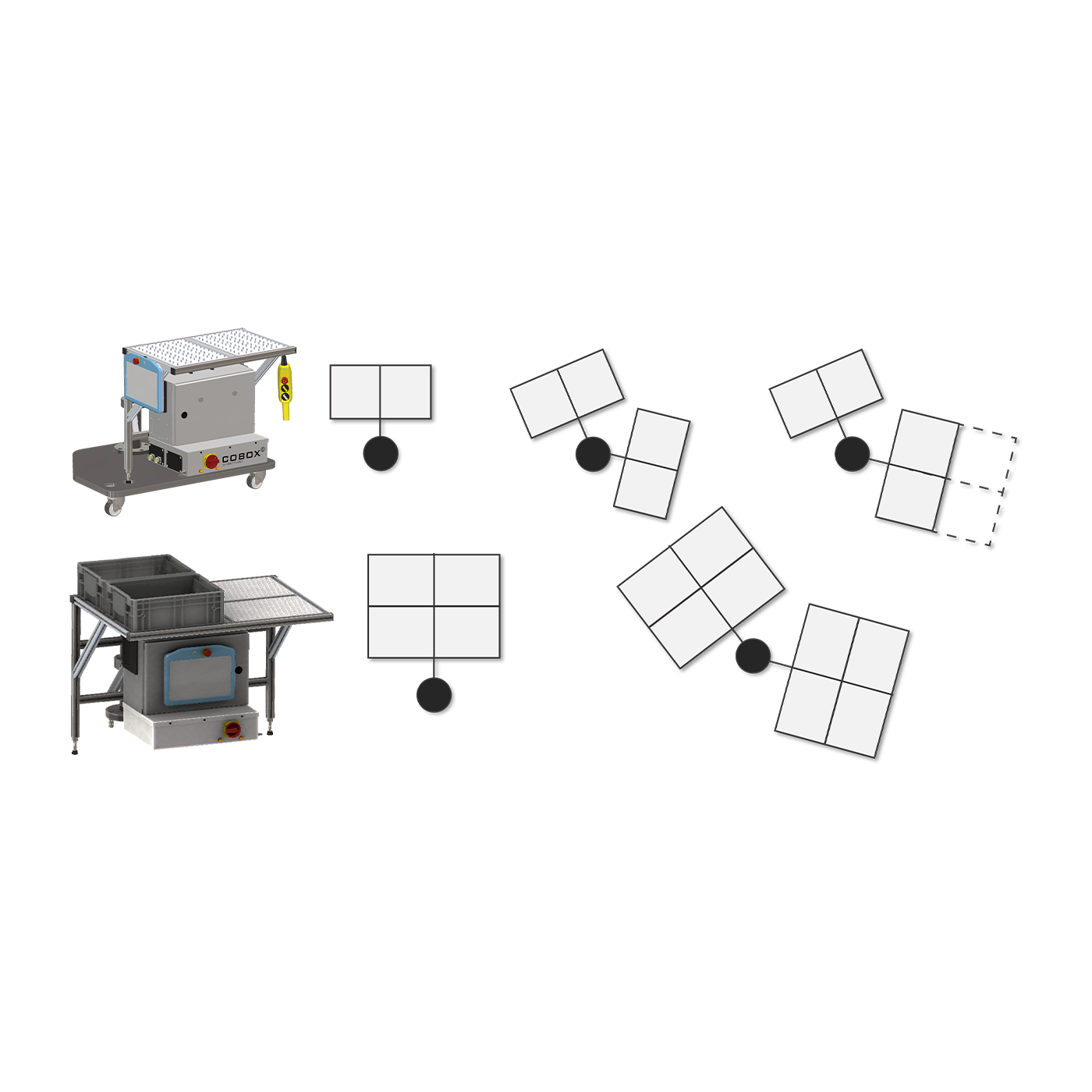

Depending on your needs, COBOX can be configured to work in a limited workspace (a single rack configuration with two work fields is a 100x66 cm outline) or to store as many details as possible and for extended unattended operation (a configuration with 3 racks of 86x66 cm).

It is possible to use a rack of 86x66 cm with 2 working fields or a rack of 86x66 cm, in any configuration of a stand with one, two or even three racks.

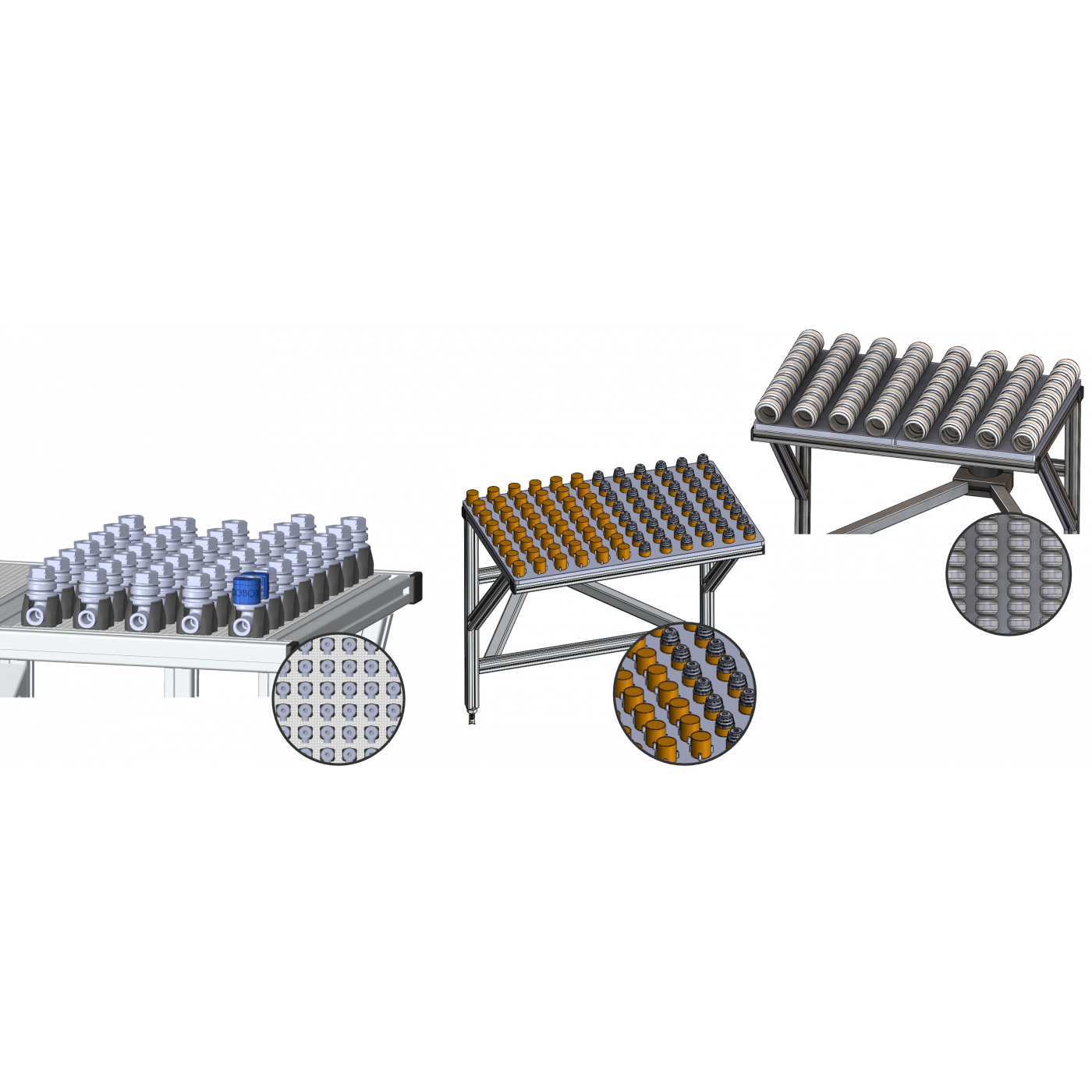

The design of the plates allows free adjustment of the grid of positioning pins to the shape of the workpiece, as well as quick replacement of the entire plate. In combination with dedicated overlays made with 3D printing technology, perforated plates allow precise positioning and storage of semi-finished products with irregular shapes and those with an unusual position of the center of gravity.

The COBOX design allows for quick replacement of gripper fingers and adaptation of the station to handle the next product range. The Cobot Planet team has developed a wide range of 3D models of fingers that work with grippers from Robotiq and OnRobot. Customers according to their preference can purchase gripper fingers from Cobot Planet or download 3D models and make models on their own.