COBOX vs. TWO FANUC ROBODRILL MACHINES

COBOX vs. TWO FANUC ROBODRILL MACHINES

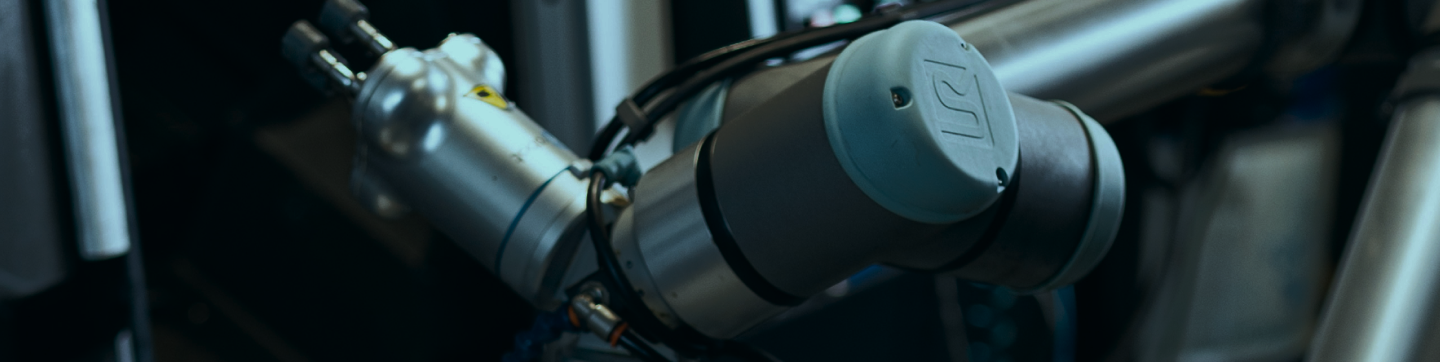

In a recent implementation, we used a COBOX to operate two machining centers simultaneously. The implementation required both advanced software options and a complex algorithm to operate the collaborative robot. Thanks to the original C-Interconnector, where the signal exchange takes place, communication between the collaborating robot and the machines runs smoothly and quickly - this allows to operate first the machine center, which reported the end of the machining cycle. This is very important in terms of reducing downtimes and fully exploiting the potential of the COBOX. This results in a noticeable increase in the efficiency of the machine park, which translates into an even faster return on investment.

We must remember, however, that in order for such implementation to be possible, the details can not differ much from each other, but should be of similar geometry. The processing time of workpieces should not necessarily be similar, as the breaks that occur throughout the cycle, we allocate to operate the second machine (in this case for workpiece A is almost 3 minutes, while for workpiece B - about 11 minutes).