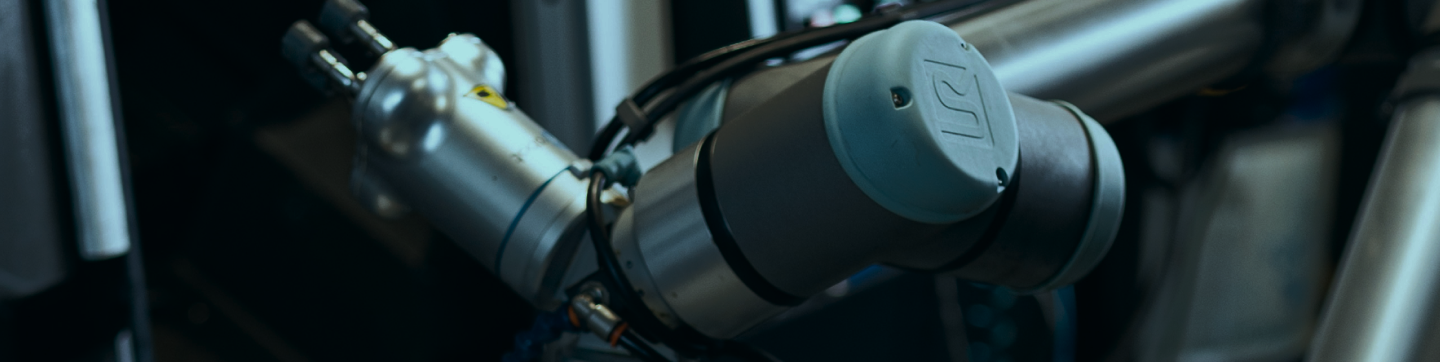

CASE STUDY: COBOX stand another implementation at a satisfied customer

Customers coming back for more COBOX stations - they are the ones who cheer us on to continue our work.

We recently had the pleasure of implementing a second COBOX stand at ZPUH Pogoda Krzysztof. The first case study of the installation and startup of the previous stand you can find here.

Automation pays off

Another purchase

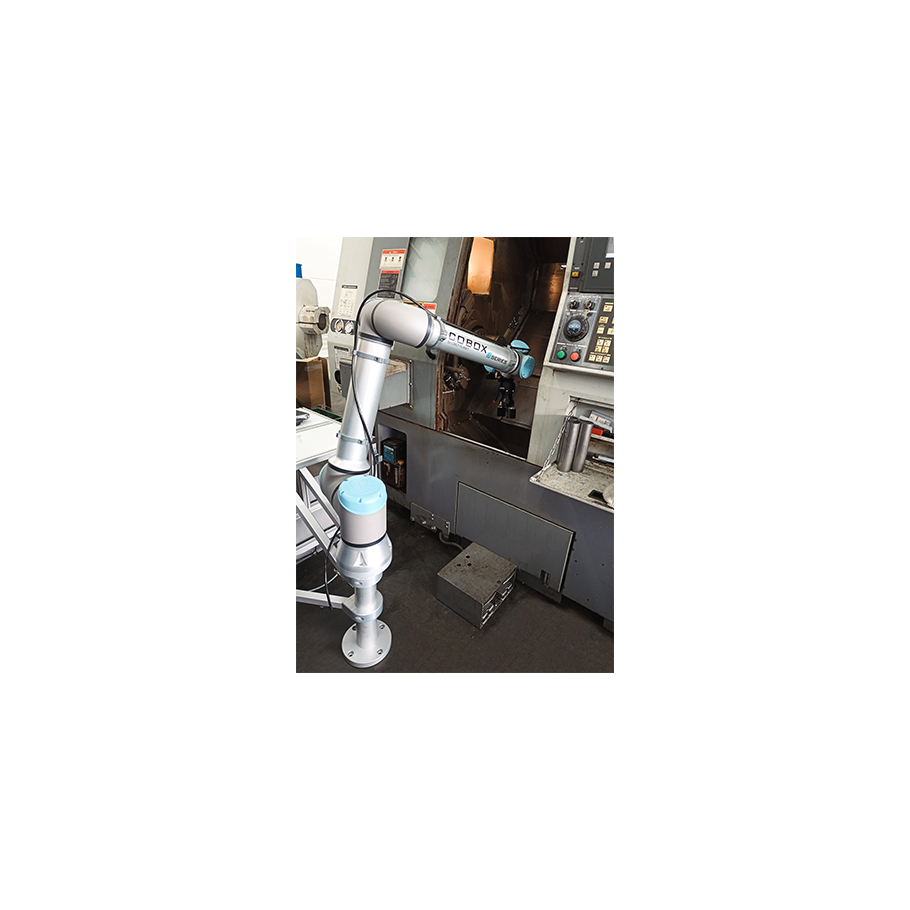

After three months of operation of the first COBOX, our client very quickly saw the advantages of automation.

Advantages of automation

Productivity and quality in a new class

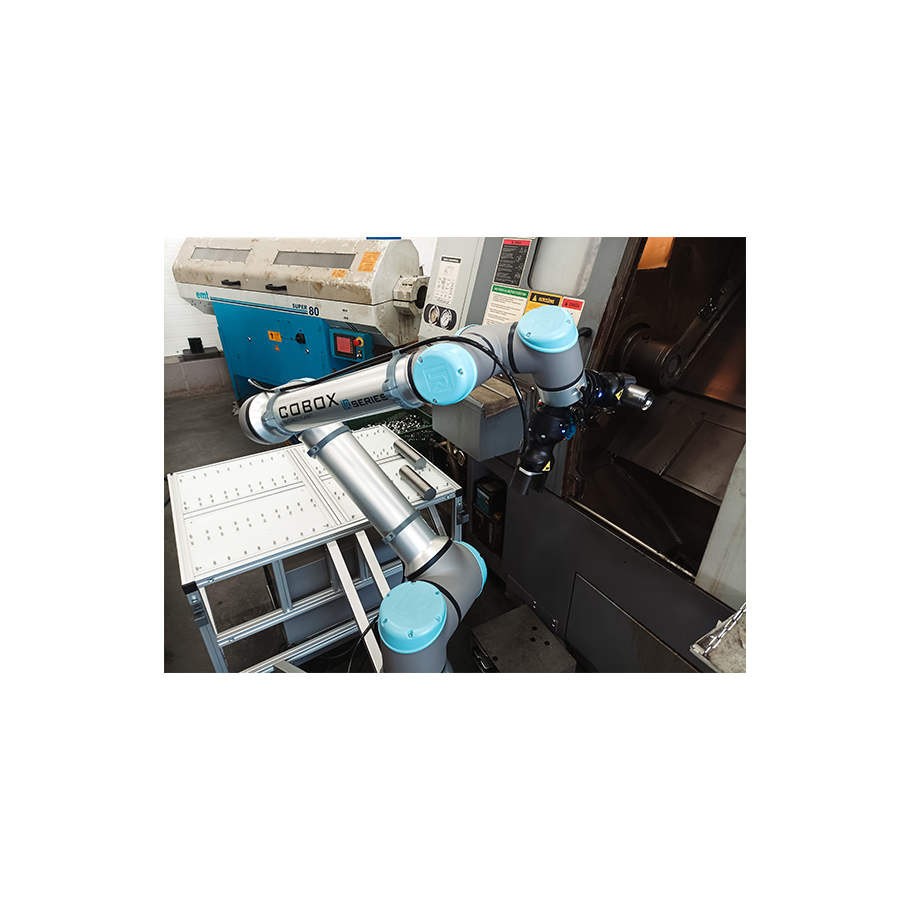

The most monotonous and repetitive operations were automated. The use of COBOX:

- raised and stabilized the productivity of the CNC machine tool,

- lowered the number of defective workpieces, as the effect of worker fatigue in handling the order was eliminated. Now operators can devote their time to more creative and engaging activities.

COBOX - ideal financing

The implementation at ZPHU Pogoda is also an example of flexible financing.

The customer took advantage of leasing with a 1% contribution. This means minimal capital commitment. With repayment spread over 4 years, the lease installment does not exceed €1,250. This was possible thanks to cooperation with ING Lease. In practice, our customer realizes savings from the implementation of COBOX from the 1st day after the commissioning of the stand (not only in terms of costs, but also in terms of cash).

Rapid implementation - case study

The workstation was implemented in just 3 weeks after the customer's purchase decision. Thanks to the experience gained by the Client's staff during the first implementation, the commissioning and handover of the stand to work took place on the day COBOX was delivered to the Client.

The example of the second COBOX implementation at ZPHU Pogoda shows all the advantages of our model of operation. Together with our Customers and Partners, we are setting new standards in automation of production processes.